Shoei Yoh was born in Kumamoto, Japan in 1940. After graduating from Keio University in 1962 with a degree in economics, Yoh went to the United States of America (USA) to study fine and applied arts at Wittenberg University, Springfield, Ohio. Returning to Japan in 1964, Yoh worked as an interior designer at International Design Associates in Tokyo, where he was involved in such projects as Readers Digest Office in Tokyo. He then moved to Fukuoka, where he worked as a designer for NIC, contributing to the rise of Fukuoka's design culture.

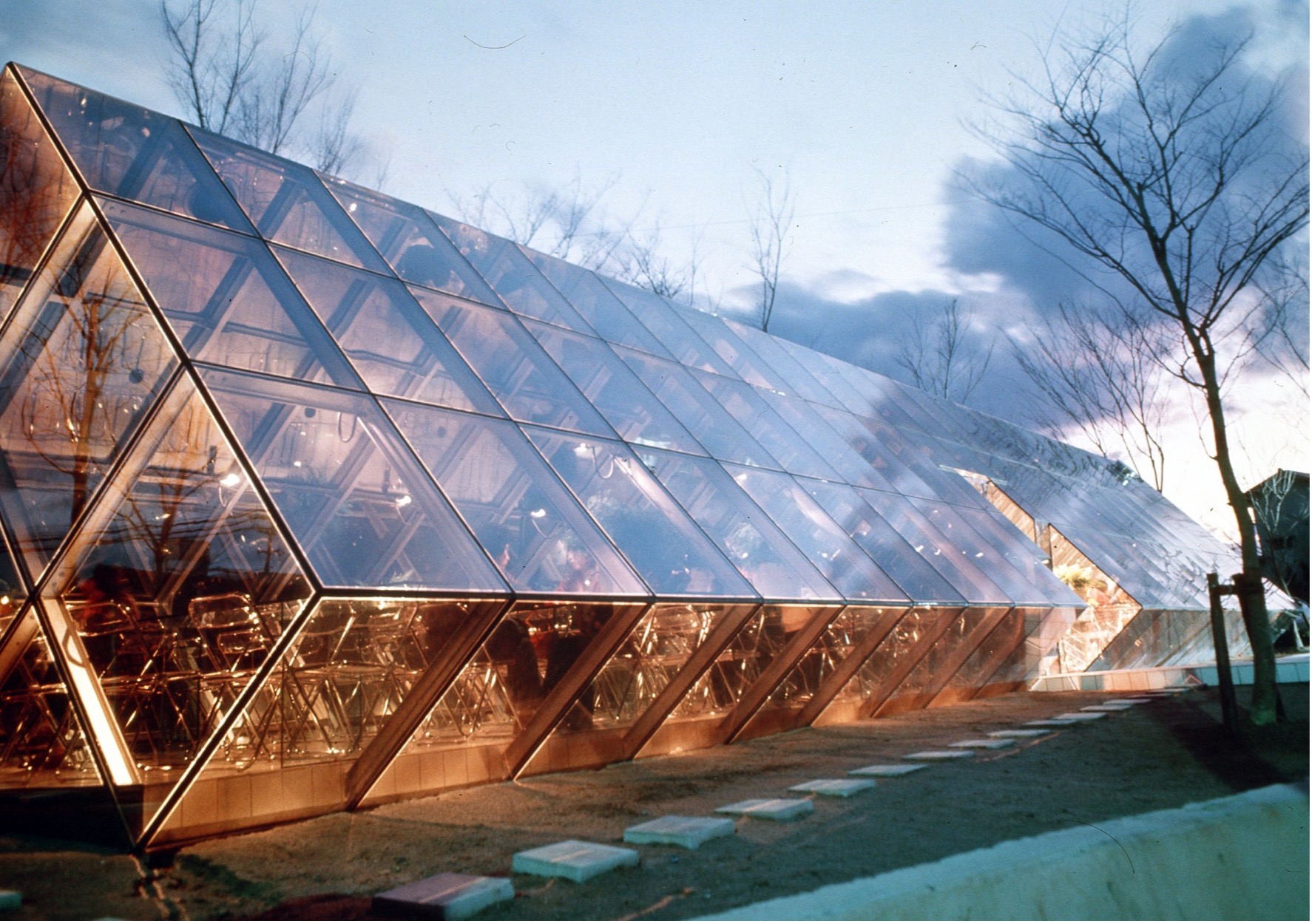

In 1970, Yoh established the Yoh Design Office in Fukuoka and began working across product design, interior design, and architectural design. His works include Ingot (1977), the first building in Japan to use four-sided structural glazing, and Kinoshita Clinic (1979), a boldly shaped building with fibre-reinforced polymer (FRP) moulded panels, both of which combine new technology with poetic space. His serial works on the theme of light, such as the House of Light Lattice (1981), have been highly acclaimed both in Japan and abroad.

In 1984, he began work on projects in the town of Oguni, Kumamoto. His series of timber three-dimensional truss buildings, developed through the Music Atelier (1986), U Station (1986), and Oguni Dome (1988), became a milestone in the modernization of timber architecture in Japan.

In the 1990s, he pursued architecture as a natural phenomenon, producing works such as Galaxy Toyama (1992) and Naiju Community Center (1994). These works, which incorporated computer analysis into the design process, are regarded as pioneering works in digital design.

Yoh's architectural and design works have received numerous accolades including Japan Interior Designer Award, 1979; Japan Architectural Association Award for Stainless-Steel House with Light Lattice, 1980; Mainichi Design Award, 1983; Architectural Institute of Japan Award for the series of timber buildings in Oguni, 1989; IAKS Award, Gold Medal, 1993. Yoh was awarded an Honorary Doctorate in Fine Arts from Wittenberg University in 2007.

Shoei Yoh has served as a visiting lecturer at Kyushu University from 1992 to 2002, and as a Professor at the Graduate School of Media and Governance, Keio University from 1996 to 2005. In 1992, Yoh was a Visiting Professor at the Graduate School of Architecture, Planning and Preservation at Columbia University.

A large collection of drawings, models, products, and materials of Shoei Yoh and the Yoh Design Office are currently held at the Shoei Yoh Archive at the Environmental Design Global Hub, Kyushu University. Smaller collections of work by Shoei Yoh and the Yoh Design Office archive are held at the FRAC Centre (Orléans, France), Canadian Centre for Architecture (Montréal, Canada); and the National Museum of Art (Osaka, Japan).

Written by Masaaki Iwamoto, 7 September 2021

2019

The Mission: Use Thinned Timber

Iwamoto: In Archaeology of the Digital, Greg Lynn cites the Oguni Dome (1988) as a trailblazing example of the use of computer simulation in architecture. In Japan, it is seen as a pioneer in postwar, large-scale wooden construction. Today, we would like to talk about the Oguni Dome from the two perspectives of digital design and timber structures.

Yoh: the Oguni Dome is a pretty old project, so I’m not sure how much good it will do to discuss it! I mean, the information about it was all documented a long time ago. That being said, the Oguni Dome still looks quite pristine after being used all this time. This year, the Japan Institute of Architects (JIA) presented it with the JIA Twenty-Five Year Award. I had no intention of putting the Oguni Dome up for consideration for the award, but a group of architects in Kumamoto Prefecture did so on my behalf. The interior gets enough natural light that no electric lights are needed in the daytime, not until it gets dark in the evening. For more than 30 years it’s been in active use––it’s not like it’s a piece of architectural history.

Iwamoto: The term “living heritage” is one that historians and preservationists have started using recently.

Yoh: That sounds like an oxymoron to me. Maybe “legacy” would make sense, but the concept of “heritage” is being misinterpreted there. For that matter, something similar could be said about the phrase “archaeology of the digital.” I mean, archaeology literally means the study of old things, but it’s being applied to modern buildings designed with computers. At the same time, Greg Lynn and the Canadian Centre for Architecture began their work in that area out of a sense of crisis, because the digital evidence for those design processes is already in danger of being scattered and lost.

On the subject of the Oguni Dome, I’d like to talk first about the social context of building with thinned timber. At that time, the mayor of the town of Oguni was a man in his thirties named Nobutoshi Miyazaki, and he had a big problem on his hands because service on the Japan National Railway’s Miyanoharu Line was being discontinued. In the old days, timber was shipped down the river and stocked by the seaside. There was an endeavor to switch over to using trains, but trucks became the main mode of transport, and because the trains were rarely used, that rail line went into the red, and it was decided that trains would stop running at a point before they reached Oguni. Mr. Miyazaki was not sure what should be done with the former train station site, and he got in touch with me after finding something about me in a book, something about how I was a young architect from Kumamoto Prefecture. He called me up directly, and asked me if I would come and have a look at the site. When I visited, I learned the biggest problem was that nobody was using the timber that resulted from forest thinning. If they couldn’t continue doing forest thinning, it would be a fatal blow for the forestry industry. After World War II Japan needed to build a lot of housing quickly, and national policy called for planting huge numbers of trees. In Oguni, what they planted were cuttings of a type of cedar called yabukuguri. The forest grew and grew and blocked out the light, so it needed to be thinned, but by this point there was nobody doing it. In the old days, thinned timber was used for the freight racks of trucks and for scaffolding, but those applications had become obsolete. Mr. Miyazaki was having them use thinned timber to make coverings for roadside ditches, since there was no other demand for it. He had tried asking architects to work with the thinned timber, but they refused because they said they were incapable of doing the structural calculations. The town didn’t know what to do with all this surplus wood. So, it wasn’t that I selected the material––that would have been the mission for any architect on this project.

Sato: It was a basic prerequisite for the project.

Yoh: That’s right. Mayor Miyazaki asked me to come up with a plan for reuse of the former train station site. Japan National Railway was granting the town 100 million yen for converting from train to bus service, plus they offered to sell the land formerly occupied by the rail line at a discount. That was the project, and I made an initial model for it, but at that stage I hadn’t arrived at a way of using the thinned timber. Although I did have, as one of my inputs, the directive to use it if it was at all possible.

- Arriving at a Three-Dimensional Timber Truss Structure -

Iwamoto: Compared to other structures, a 3D truss enables you to use shorter members. Was it the requirement to use thinned timbers that led you to the 3D truss?

Yoh: Not exactly. I first consulted Professor Teijiro Muramatsu, and went to see Ise Jingu Shrine. Japan has a long history of wooden construction, and I wanted to find out more about past examples. However, I realized that Japan didn’t have a track record of building large spaceframes with small-diameter timbers, so I wasn’t sure where to turn. Just then I learned about Multihalle in Mannheim, designed by Frei Otto. When I saw what he was able to do with thin timbers, it was like the scales fell from my eyes.

Iwamoto: Did you see the Mannheim building in person?

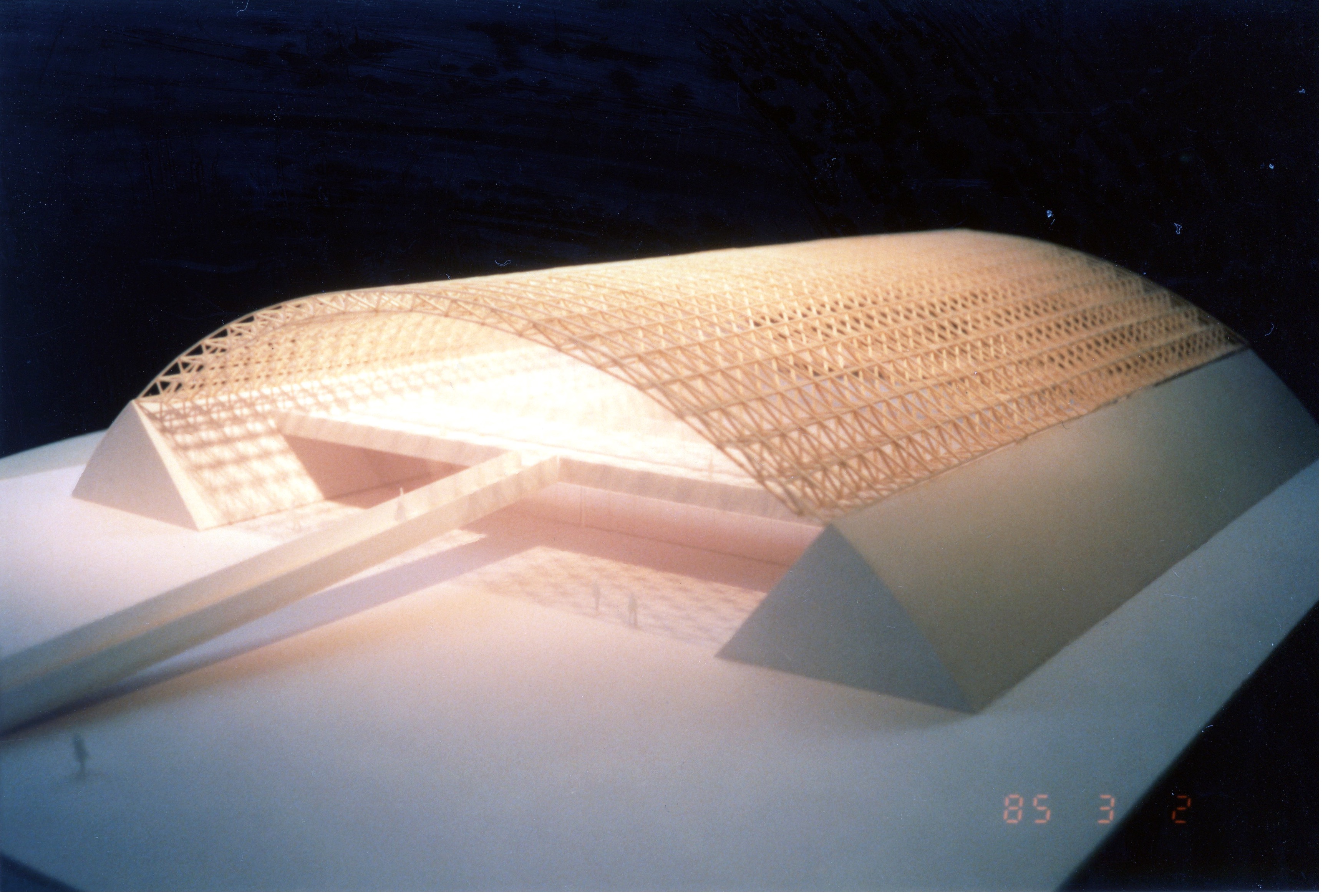

Yoh: I saw photographs of it. For the Oguni project, I first asked Yoshihiko Morikawa from Atelier Furai to handle the structural design, then Morikawa introduced Professor Gengo Matsui of Waseda University. That was because Professor Matsui had designed the timber structure for Christopher Alexander’s Eishin Gakuen Campus (1985). Morikawa and I went to visit Professor Matsui at home, and he showed us the Holzbau Atlas, a German book on wooden buildings. In that book I found the hall by Frei Otto and saw that thin timbers could be used to construct large spaceframes. At the time I had projects by Norman Foster in mind, like the HSBC Main Building, Hong Kong (1985) and the Sainsbury Center for Visual Arts (1978). I had a strong admiration for the structural. Foster’s works included a plan for a barrel vault, and I wondered if I could do something like that with a timber structure.

Iwamoto: And that’s how you came to collaborate with the Gengo Matsui Lab at Waseda University.

Yoh: There was a long, difficult process with the series of projects from Music Atelier (1986), the first use of 3D timber truss, to the Oguni Dome, and they were all collaborations with Professor Matsui and Mr. Morikawa. At the Eishin Gakuen Campus, Professor Matsui confirmed safety through photoelastic testing rather than just calculations. In other words, structural integrity was verified in terms of dynamics visible to the eye. Also, with timber structures the problem is how to deal with the joints, but Gengo Matsui Lab had done experiments where they injected epoxy resin into holes in the tips of bolts in order to transmit stress at the joints, and published papers on it. If stress could be transmitted as axial force, the 3D truss became an option. I thought, this is it! I was overjoyed, I asked Professor Matsui to come to Kumamoto and we made the rounds at the Kumamoto Prefectural Office. I explained to the people in each department that a timber structure was going to be fine, because I was going to have Professor Matsui’s oversight. I got the sense that things were going well, and with this newfound confidence, I held an exhibition featuring a lot of different experimental materials in the design gallery at Matsuya Department Store in Tokyo.

Sato: Did you exhibit a test model?

Yoh: Yes, I exhibited a test model that enabled checking of deformation. There was no test data on that for timber, and for tension members in particular there was no information at all in Japan. It was all a “black box.” A 3D truss is subject to tensile force too, not only compressive force, and that’s why the joints are crucial. So epoxy resin, which allows deformation at the millimeter unit level or less and can transmit force, became indispensable. Until then, I had used silicone resin on a lot of different projects.

Iwamoto: For example, the Ingot Coffee Shop (1977).

Yoh: With the Ingot, two-component silicone was used to promote elasticity of the joints between pieces of glass. Ultraviolet curing adhesive was also used to make glass tables, but this adhesive doesn’t allow for any deformation. Because of this experience, I thought it using epoxy resin was a great idea. Professor Matsui told me that epoxy has nearly the same Young’s modulus as wood. And since the resin is freely movable until it hardens, you can get dimensional accuracy down to ± 0. It was at this point that I finally arrived at the 3D truss. I held the exhibition in Tokyo, called Forms in Wood. Then, some people who had been dispatched from the Kumamoto Prefectural Office to the Ministry of Construction saw it, and I had trouble on my hands. Since I was trying to build a timber structure of over 3,000 square meters in Kumamoto Prefecture, it was decided that it needed to be evaluated. Suddenly, I needed to get the structure accredited under Article 38 of the Building Standards Act. Article 1 of the Act states that the objective of the law is to establish minimum standards in order to protect the life, health, and property of the nation, and that means a project can’t go forward unless its safety can be verified. But then Article 38 says the law is not applicable to materials and building techniques not envisioned in the law. The only option is a process that involves spending huge amounts of money to conduct tests, getting the plan evaluated by a committee of highly knowledgeable experts, and having its safety verified. Our little firm, and the town of Oguni, went through this evaluation process for a series of projects: the Oguni Bus Terminal (1987), the Forestry Center (1987) and the Oguni Dome. But actually, the first project to be evaluated was the Music Atelier (1986), a music facility, for which Morihiro Hosokawa was the client.

Iwamoto: At the time, Mr. Hosokawa was the governor of Kumamoto Prefecture. Did the prefectural project get moved ahead of the town project, in terms of the timeline?

Yoh: That’s right. Kumamoto had this concept on the drawing board that they were calling Technopolis Center, but evidently Mr. Hosokawa wasn’t sure what he thought of it, so I was asked for my opinion. As we were discussing it, we came up with the idea for an outdoor concert hall in Minami-Aso, where there’s all this wide-open space and tens of thousands of young people could gather, and we came up with the concept of a “Sound Village.” The event venue would be called ASPECTA, a combination of “Aso” and “spectacle.” He told me I could decide on the site. We got artists and designers to come down from Tokyo, and productions of Osamu Tezuka’s Phoenix and Bill Fontana’s sound sculpture were staged. While I was working on the venue design, Mr. Hosokawa also asked me to design a small music atelier using thinned timber in Oguni. This was the first building I ever designed that was funded by taxpayers.

Iwamoto: Did the ASPECTA design predate the plan for the former train station site in Oguni? Was the 3D timber truss used for the Music Atelier because the Oguni project was going on concurrently? What can you tell us about the relationship between the two?

Yoh: The two were proceeding in parallel. At the time, the deputy chief of the Kumamoto Prefectural Office civil engineering section was a man named Riku Okawa who had been dispatched from the Ministry of Construction. I didn’t hear about it directly, but evidently he was advising Governor Hosokawa. What he said was that there was a proposal to build a large timber structure in the town of Oguni, but the Ministry of Construction wasn’t sure how to handle it because there was no precedent, and under these circumstances, the prefecture ought to take the initiative. The problems with the forestry industry that Oguni Mayor Miyazaki faced were the outcome of Japan’s national policy. Also, at the time there were imported materials coming in due to US trade pressure, engineered wood and two-by-fours were becoming more common, and there was a sense that we should avoid using conventional construction methods. Building with wood was the Japanese tradition, but from a technical perspective it was a black box. If we were going to try to tackle this issue somehow, why not try a small project to begin with? That was the idea.

Iwamoto: And that was the Music Atelier. The prefecture-led project got underway, and that helped to propel the Oguni town project, is that right?

Yoh: Yes, the prefectural project went ahead first. From the evaluating committee’s perspective, it was the same kind of project, but with the Music Atelier, the Oguni town council was not involved. In fact, the story is a bit more complicated, because also in 1986 there was an event in Kumamoto called the Kumamoto Greenpic, and we designed a timber-lattice shell for the pavilion, which was basically an imitation of Frei Otto. That was constructed around the same time as the Music Atelier.

- Opening the “Black Box” of Timber Structures -

Yoh: After the Music Atelier got ministerial approval under Article 38, dozens of experts came down from Tokyo. After this, the timber structure “black box” began to open up. University of Tokyo Professor Hideo Sugiyama and others had lots of questions. What did we think we were going to do about this and that? What about the tree ring widths, what about the drying process, what about rotting over time, what about knots in the wood, what if cracking occurs? We also debated how the material ought to be selected. The Oguni forestry cooperative prepared samples, each one of them was tested, each time a paper was written on it. So Professor Matsui was happy, and the students in his lab were happy too. Because with wood, fracture testing was nothing to be afraid of [laughs]. None of the things I just mentioned were covered in the official structural standards for timber. Nothing about tensile strength, for example. Do you know why you can’t conduct tension tests on wood? Take a chopstick––if you push on it or bend it, it’ll break immediately. But what happens if you pull it? There’s no way you can tear it by hand. That’s why we joined the ends of the members with bolts, so both ends would be immobilized, and then we could perform tests. That’s how this structure got started.

Sato: Even with today’s technology, we can only get partial experimental data on tensile force for timber. The mechanisms to grip the ends of the members while pulling are still lacking.

Yoh: Is that so? Everything ought to be tested: large cross-sections, small cross-sections, thick bolts, thin bolts. When tension tests are carried out on bolted joints, the bolt always breaks first. This means the safety factor for timber is many times higher than it actually needs to be. Professor Matsui described what we were using as “orthotropic materials” – with material properties along three mutually-orthogonal axes – but in any case, wood is a form of fiber. Carbon fiber is extremely tension-resistant, it’s so strong that it’s used in motor vehicles and airplanes. However, it’s epoxy resin that binds one part to another. The carbon is strong, but it’s vital to think about what’s connecting it. We had to focus on that, and so we owe this project’s success to Professor Matsui’s epoxy pressure injection.

Sato: If we look at the series of projects in Oguni, from the Oguni Bus Terminal to the Oguni Dome, we see the details of bolted junctions becoming more refined. At the Oguni Dome the bolts are concealed, and it looks extremely clean and streamlined.

Yoh: Each time we did a test, we made progress in opening that black box of timber structures. In the beginning, the washers for the bolts were not circular, but very large square ones. I believe that at that time, structural experts thought it was better to have a larger tightening surface. Keep in mind that these were some of Japan’s top engineers. But we demonstrated that there was no need for tightening to begin with. The bolts just needed to stand up to compression and tension, and in that case round washers would be fine. With each project we did more tests and made more improvements, and finally, for the Oguni Dome we used pin joints. I believe that was a big step forward. Every one of the details was something that emerged from test results. After all, there’s nothing you can put your faith in besides testing.

Iwamoto: Did people from Yoh Design Office observe the tests at Gengo Matsui Lab?

Yoh: No, we didn’t. Professor Matsui carried out the necessary tests. He and Mr. Morikawa appeared at each of the evaluations for us, too. With dozens of highly respected experts on these evaluation committees, my office members on our own would have been thrown to the wolves [laughs]. Usually, only major architectural firms and big building contractors appear in front of these committees. It costs a lot, and everyone tries to avoid it if at all possible.

Iwamoto: So Gengo Matsui Lab didn’t do the structural calculations. What they did was test the joints and so on, for the core support that makes a timber structure feasible?

Yoh: That’s correct. Professor Matsui provided us with fundamental know-how and helped us with handling the wood. Because timber was being treated as a “new material,” and orthotropic materials are different from concrete or steel. So it was like exploring uncharted wilderness.

The Oguni Dome also underwent a disaster resilience evaluation. This is something completely separate from the structural evaluation. The Building Standards Act originally prohibited timber structures larger than 3,000 square meters, but the Ministry of Agriculture, Forestry and Fisheries (MAFF) was extremely displeased with that. They blamed the Ministry of Construction’s ban on large-scale wood structures for the decline of the forestry industry. The Ministry of Construction wasn’t sure what to do about it, either. There were no grounds in particular for differentiating a 3,000-square-meter structure from a 3,001-square-meter one. During the Oguni Dome project, there was conflict between MAFF and the Ministry of Construction. Then someone from the construction ministry advised me to go and visit Tacoma Dome in the US, which was the world’s largest wooden structure at the time. I traveled to the US at my own expense, and one thing I saw during on-site observations was that they use fire hoses if a fire needs to be extinguished. When I reported this to the ministry, they told me to install sprinklers instead of fire hoses, but then the Ministry of Home Affairs, which had jurisdiction over fire safety at the time, told me there was no need for sprinklers. In the Ministry of Construction’s view, a 3D truss structure built with timber was likely to catch fire, and they argued that sprinklers were necessary. Of course, all a sprinkler does is put out the fire source if it’s right beneath it. However, the Ministry of Construction insisted they were necessary, since this was one of the conditions on which they had approved the project. In the end we went along with that, but even now, looking back on it I regret having wasted so much taxpayer money. We had already ensured safety by verifying the time needed to evacuate through simulations.

Iwamoto: So, setting aside the situation in Oguni at the time – where you were required to use thinned timbers – what, in your view, are the distinctive characteristics and strong points of wood?

Yoh: This goes back to when I was first establishing my office, but back then I was actually hired as an interior designer, and came to Fukuoka to design furniture for the Nishitetsu Grand Hotel (1969).

Iwamoto: The hotel designed by Shizutaro Urabe.

Yoh: Yes, by Urabe. For the furniture material, I wasn’t thinking of anything besides hardwood––something like cedar was not an option. When working on the design, I weighed the pros and cons of various hardwoods, like oak, Japanese maple, teak, rosewood, cherry and so on. There are all kinds of woods, and they have their own suitable forms and applications, but I don’t really understand what’s going on with wood nowadays. I mean, you’ve got laminated wood, you’ve got nonflammable wood and so forth, but whether it’s natural or processed wood, you have to use hardware or some adhesive like epoxy for the joints, not traditional construction methods. It seems to me that making sure visible surfaces are straight-grain, or eliminating knots, all that is just superficial. And as to what we’re seeing today, I understand there are cost concerns and all, but just adding on some wood to make things look nice is absurd. Like the new Olympic Stadium [in Tokyo], where wood is tacked on as a nice-looking decorative surface––what’s the point of that? It’s all just a kind of image-based branding, like “wood is warm, wood is friendly,” that kind of thing. Wood has all kinds of merits, it has low thermal conductivity, it feels good on the feet, it works as a moisture-absorbing and sound-absorbing material, so there are many advantages to using it for the floor of a school classroom, for example. But to go out of your way to use it as a structural material just to project a certain image, that’s simply pandering. It’s superficial, like printed plywood or something. We used it for the Oguni Dome because we needed to use thinned timber for the town’s sake. To present some woody surfaces just for their sentimental appeal, that’s something I can’t stand. It’s like architects or designers get a free pass as long as they throw in some wood, and I think they’re deceiving the general public.

- The Computational Design Process -

Iwamoto: So, can we talk about the Oguni projects from the standpoint of digital design?

Yoh: The Music Atelier was the first project to be evaluated, and the second was Oguni Bus Terminal. During the design of Oguni Bus Terminal I began having lengthy telephone conversations with Kenshi Oda of Taiyo Kogyo. For 3D trusses, Taiyo Kogyo was using steel globe joints made by the German company MERO. I didn’t know of any replaceable joints for chord members besides the MERO globe joints, so I wanted to work with Taiyo Kogyo. As it says in Greg Lynn’s book, Taiyo Kogyo had a contractual relationship with MERO and had a track record with an analytical program for truss structures. Oguni Bus Terminal is a circular building, and while looking at the results of simulations, we discussed and discarded various options for how to divide it. Would this work? Would that work? With a circle you have unlimited options, you could divide it by 36, by 18, by 20 and so forth.

Mizutani: There was a feature article in Shinkenchiku where you were quoted as saying computers are modern-day magic. Did you get that sense when you were working with Mr. Oda?

Yoh: Yes, and I still think computers are modern-day magic. In data terms, a timber structure was a black box, and Professor Matsui pried that black box open to the point where we were able to program simulations. Once you can keep deformation below a certain level, you can make calculations. When that becomes possible, then you can modify the conditions and do new calculations each time. You can simulate the entire process from the origin to the completion of the design.

Mizutani: What was it like working with Mr. Oda? How often did you alter conditions, such as the overall form of the Oguni Dome or the span dimensions? What were your discussions like at the time?

Yoh: I can’t remember them very well, but we spoke on the phone for hours and hours. To me, Mr. Oda was like a human computer. There are all these nodes, and the stresses of the eight members connected to it appear as numerical data: I could see this and still not understand, to me they were just numbers. The point was that they had a program to make those calculations.

Sato: When you were designing the interior, who decided, for example, the size of the space under the roof?

Yoh: I decided things like that at my own discretion. For example, when I was asked what the rise should be, I provisionally set it at 1.2m or 1.4m.

Iwamoto: So, is it correct to say that the framework model was the starting point for your working with Taiyo Kogyo?

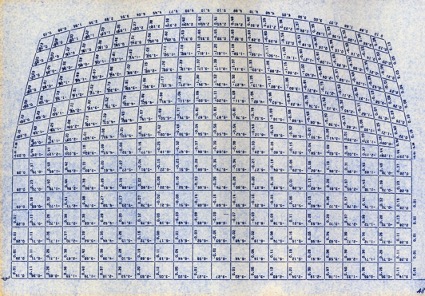

Yoh: Yes. First, I bought some balsa wood and made the model. We were still a long way from checking stress on members. First, we needed to get the big picture. Were there any points where the structure would sag or buckle? They would tell me where the critical points were, and I’d correct them, change the fulcrum points and so on. Timber is lighter than steel or concrete, you know. Light, but strong. However, being light has its drawbacks. The material can be blown upward by wind pressure. In a 3D truss, exposure to wind can bring tensile force to bear even on compressed members, which are also bearing the load of their own weight or snowfall accumulation. Tension members are not a problem. However, when tension and compression are reversed, compressed members can buckle due to the slenderness ratio. For that reason, we made the compressed members thicker. Various simulations were required – for lateral force, for wind pressure, for the weight of accumulated snow – and based on each of these we prepared members with maximum force resistance. There were dozens or hundreds of types of members, and I thought it was analogous to a community. The diversity of members expressed the ideal of a community created by men and women of all ages, short and tall people, all kinds of people working together. Of course, it was the MERO globe joints that held this “community” together.

Mizutani: The idea that members connected by nodes form an overall network, like a community, is interesting. And then you can find weak points in the network using computer simulations. I guess you can get a structural sense of the entirety as a kind of living thing, which you couldn’t get from the members as individual units. Did you come to understand simulations like this little by little, through your conversations with Mr. Oda?

Yoh: Yes, it was a real learning experience. I mean, I was totally ignorant at the start. Although I did know a bit about computers since I had majored in economics at university.

Iwamoto: Was your background in studying econometrics at Keio University useful when performing computer simulations with Taiyo Kogyo? That’s one thing that Greg Lynn points out.

Yoh: What I focused on at university was demand forecasting. This study involved increasing the number of parameters in plural equations and boosting the accuracy of predictions. However, this had no direct connection to architecture. I think I mentioned my experience with computers to Greg Lynn without thinking too deeply about it, but the fact is, I can’t even type.

- Following Natural Phenomena and Parameters -

Iwamoto: What is your view of learning about optimization from natural phenomena? That’s something we see in the architecture of Frei Otto, and that tendency seems to be present in your work as well.

Yoh: Well, I would say that test results are the most important thing. The testing process itself is a natural phenomenon. The “wet blanket” that Greg Lynn describes is a good example. You put a blanket over something, a wet one, and natural phenomena occur. What happens if four people hold the sides of the wet blanket? The form it takes is a natural structure, the structure that gravity produces. Or the final form that results from its own weight. Then, take the example of the Spanish architect Antoni Gaudi. He suspended a chain to make a catenary curve, and turned the shape upside down to make a compression arch. You can call this biomorphic, or naturally phenomenological, the terminology is not important, but in any case nature produces a 3D curvilinear surface. Today I’m convinced that at the Oguni Dome, changes in stress were determined in the context of the rise that I arbitrarily decided on. I had my own ideas about how to do this and that, and they made calculations based on those ideas. Mr. Oda told me things like “the arch is a bit low, if it was a bit higher we could get an arching effect” and so on, we had an ongoing back-and-forth like that. Making changes to the form to let in more light, for example. So while the initial design was a barrel vault, like Foster’s which I admired, we ended up modifying it considerably.

Iwamoto: According to Natural Structures by Frei Otto et al, structural testing using chain suspension was being carried out before Gaudi, but it was Gaudi who first produced designs based on the forms that emerged from these tests. Among your projects, more than the Oguni Dome, it seems that the Odawara Municipal Sports Complex Proposal (1991) is a direct formal reflection of the computer’s output. Does that sound right to you?

Yoh: For the Odawara project, the locations of the columns were first decided based on room size. The positions and heights of the columns were then varied based on other conditions. Another consideration was how to take in and reflect light. Computers are really wonderful in that they can handle architectural operations like these.

Iwamoto: Meaning it’s easy to change the parameters?

Yoh: Absolutely, you just input parameters to the computer and you can model any form you want. But you’re not just producing a computer-graphic rendering, the most important part is structural analysis. Though apparently a lot of graduates of Columbia University end up in Hollywood doing computer graphics work.

Iwamoto: When designing the Oguni Dome, had you already arrived at the method of changing parameters as you proceeded with the design?

Yoh: At that point I hadn’t thought about it that deeply. With the Oguni Dome, just selecting the chord members was enough of a challenge, it was an enormous amount of work.

Iwamoto: So, the Odawara Municipal Sports Complex Proposal was a more straightforward reflection of the computer’s output than the Oguni Dome was?

Yoh: That’s basically right. But in between those two, there was the process used for the Galaxy Toyama Gymnasium (1992) project. After the Oguni Dome was completed, I saw a competition proposal by Arata Isozaki for a gymnasium on Montjuic Hill in Barcelona. The plan involved 3D curvilinear surfaces, and I thought, that’s great, what a marvelous age we’re living in, I want to design something like that. However, even though Isozaki’s project was selected, he was forced to change the method and the technology. The new plan was the Pantadome, designed in collaboration with Mamoru Kawaguchi. That was really unfortunate, but it made me think it was nonsensical to arbitrarily design 3D curvilinear surfaces, that is, sculptural forms that aren’t rational or practical. Unless they’re governed by natural phenomena, 3D curvilinear surfaces require a tremendous effort to realize. On that subject, something similar happened with the Osanbashi Yokohama International Passenger Terminal project. The selected competition proposal (1995) envisioned an arched structure, but in the end it was built as a folded-plate structure.

Iwamoto: When working on the Galaxy Toyama Gymnasium, did you have the idea in mind, from the start, of conforming to the computer’s output rather than designing forms at your discretion?

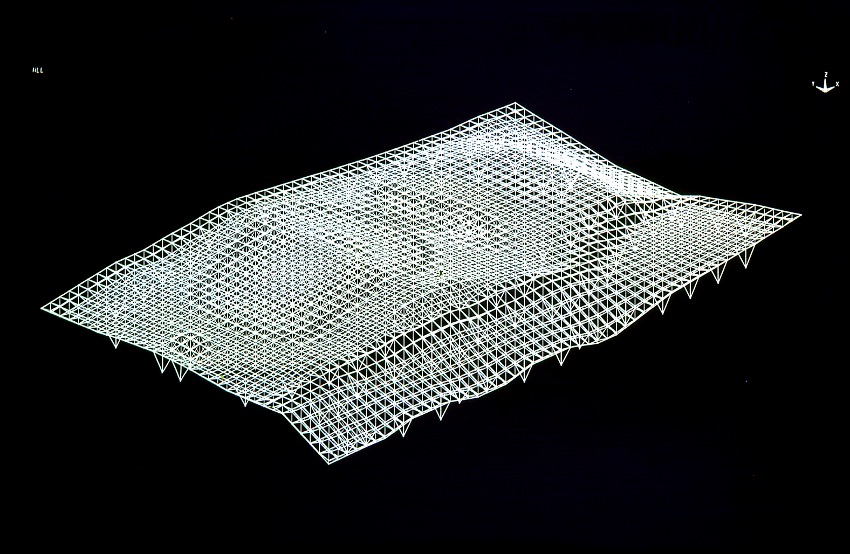

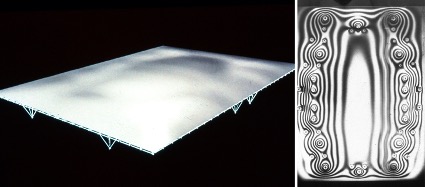

Yoh: I did. For the Galaxy Toyama Gymnasium, I designed a cantilevered 3D truss roof. In Toyama the snow can pile up to three meters, so a flat roof is going to undergo severe deformation. I got the lab to calculate numerical values for this deformation using a computer simulation, and determined the positions of pillars based on this data. Professor Matsui also conducted a photoelastic test. The results of the computer analysis of deformation were almost the same as the striped stress pattern that appears in the photoelastic test, and we were able to verify that the two were in agreement. Seen from the inside, this 3D truss resembles a galaxy. The periphery has a uniform height, but in the interior, the nodes are at varying heights.

Iwamoto: And when a 3D truss is structurally optimized, the thickness of trusses continuously changes?

Yoh: Right. For example, I wanted to set the truss rise at 2:3 with respect to the horizontal line of the periphery, and I designed it at my discretion, while taking into account the drainage gradient and how it would appear when looking up from below. The computer made it easy to decide on the final design. I mean it was easy for me––I’m not sure how easy the analysis was, it may have been extremely difficult [laughs].

Iwamoto: So you had a back-and-forth with Mr. Oda from Taiyo Kogyo. For example, you looked at analysis results and talked about things that might be adjusted, that kind of thing?

Yoh: Yes, like changing the locations of the columns or changing fulcrum points. Or deciding that one column wasn’t sufficient in a particular place, and maybe there ought to be three. I got a sense of the degree of freedom there was in this process. So then, while the Galaxy Toyama Gymnasium was under construction, I submitted a proposal for the Odawara Municipal Sports Complex competition, but it was eviscerated by one of the jury members, Professor Kawaguchi [laughs]. He said the whole idea was incredibly obvious. But in fact, the Odawara building was quite a few orders of magnitude larger than any previous projects. When you compare them, you see the space is really huge. With this project, there was absolutely no point in making the exterior wall a uniform height. The required height was determined separately for each room, and locations of columns were decided. The parameters changed, resulting in a design that was very topological. Although no one noticed this whatsoever, except for Greg Lynn.

Iwamoto: It seems that the design approach evolved over the course of this series of projects––the Oguni Dome, the Galaxy Toyama Gymnasium, the Odawara Municipal Sports Complex Proposal. In Oguni, you designed the arching forms at your discretion. In Toyama, it was decided that the four sides of the building exterior would be flat, and the surfaces were deformed in a vertical direction. And with Odawara, there was nearly free-form manipulation of the morphology, including the exterior wall. Over the course of these three projects, large parts of the design process gradually shifted to be more parameter-oriented.

- A Pioneering Project Emerging from Collaboration -

Mizutani: A little while ago, you said you weren’t sure how difficult the computer simulation process had been. But, in Greg Lynn’s interview with Mr. Oda of Taiyo Kogyo, Mr. Oda recalled that you never made any unreasonable requests. Some suggested that the Osanbashi Yokohama competition proposal lacked structural understanding of complex forms, but even at that time, you had a grasp of the structural characteristics of free forms, and were able to work with Mr. Oda without making impossible-to-meet demands. It seems to me that you were cultivating a unique sensibility around this time.

Yoh: Mr. Oda is very persuasive, and he’s willing to do whatever it takes to persuade people. During conversations like these, I wouldn’t get off the phone until I was satisfied with how things were going, and he understood that there was no moving ahead to the next step until we were in agreement. I was no digital pioneer, Taiyo Kogyo was already there ahead of me. In terms of applying this technology to timber structures, Professor Matsui put forth an enormous amount of energy, and I think he deserves more recognition for it.

Iwamoto: Did Gengo Matsui Lab and Taiyo Kogyo ever interact directly, without you as an intermediary?

Yoh: There was no direct relationship between them. I should also say that in terms of improving my understanding of timber, I owe a great debt to the Oguni forestry cooperative. They collected a large number of timber samples for testing at Gengo Matsui Lab, and without these the Oguni Dome would never have been built. One thing we discovered is that yabukuguri cedar is superior to other species. Cedar’s performance varies depending on region and so forth, and the Oguni cedar we were placing our faith in – a variety of yabukuguri – has been known for its strength since old times. Apparently it was used to make carrying poles. Its Young’s modulus is that high.

Iwamoto: Did the forestry cooperative help out in other ways besides providing samples for testing? Did you have their cooperation during construction as well?

Yoh: Not so much construction as production. The forestry cooperative sawed the material, dried it, and injected the epoxy. They also observed the inspection of product dimensions and precision. Taiyo Kogyo assembled the parts, and after the final jacking down we saw that things were just as planned. Members of the town council were always worrying––is this really going to work, why are you using thinned cedar timbers when we have hinoki cypress available, that kind of thing. Another thing I heard time and time again was that the structure of the Oguni Dome used far less timber than other buildings.

Iwamoto: So they advised you to use more timber?

Yoh: Mayor Miyazaki was trying to aid the forestry industry by promoting the use of thinned timber, but as they said, the amount of wood used for the Oguni Dome was small. In a standard building, they don’t make the kinds of calculations we did, and a large amount of excess timber ends up getting used. For example, a lot of thick wood beams were used for Mokkonkan (1988), which was built in Oguni around the same time. From the townspeople’s perspective, the more wood used, the better. It was hard to get people to approve of a building that minimized the volume of timber used. Designing a building is one thing, but moving the needle of public opinion, that’s something else again.

Iwamoto: From what we’ve heard today, it seems clear that the Oguni Dome emerged from your collaboration with Gengo Matsui Lab, Taiyo Kogyo, and the Oguni forestry cooperative.

Mizutani: My impression is that you, Mr. Yoh, are viewed as the first architect with a firm grasp of digital technology and engineering. It seems valid to say that there was no one before you who had a deep understanding of both computers and timber construction technology, and applied it to design. I think you were a pioneer in terms of physically grasping the fundamental nature of technology and engineering and applying it to design.

Yoh: I’m happy to be viewed in this way, but there were various vital contributions along the way. The Oguni Dome would never have happened without the passionate commitment of the client. The townspeople were very nervous about the whole thing. But once it was completed, it became a place that people enjoyed. I hear it’s also the designated evacuation site if disaster should strike.

Iwamoto: When I visited Oguni recently, the townspeople were looking forward to a sumo tournament coming to the Dome. They were talking about the need to prepare a sumo ring. I felt like I could understand why the Oguni Dome has been so beautifully maintained over the past 30 years.

Yoh: You can have concerts at that dome, you know. Concerts with a symphony orchestra, that’s how good the acoustics are.

Kyushu University Ito Campus

July 5, 2019

Masaaki Iwamoto

Architect Masaaki Iwamoto was born in Tokyo in 1982. After completing the graduate program at the University of Tokyo in 2008, he worked at Kazuhiko Namba + Kai Workshop. From 2011 to 2015 he was partner and head of the Ho Chi Minh office of Vo Trong Nghia Architects. In 2015 he was Specially Appointed Professor at Tokyo Metropolitan University and co-founded ICADA. Iwamoto is currently Assistant Professor at the Kyushu University Graduate School of Design. Notable works include Knothole House (2017), TRIAXIS Suma Kaigan (2018), and Kyushu University Biolab (2019).

Akihiro Mizutani

Architect Akihiro Mizutani was born in Aichi Prefecture in 1983. He earned a doctorate in engineering and completed the doctoral program at Shibaura Institute of Technology in 2013. He was a project contractor for Kengo Kuma and Associates in 2009 and worked at Saito Associates from 2010 to 2014. Mizutani became a doctoral research fellow at Shibaura Institute of Technology in 2013, Assistant Professor at Toyohashi University of Technology in 2014, and instructor at Toyohashi University of Technology in 2017, and is an instructor at Tokyo Denki University and Shibaura Institute of Technology.

Toshiaki Sato

Born in Kanagawa in 1982, Sato specializes in seismic engineering, and particularly in wood structures and materials. After graduating from Tokyo University of Science, he was Engineering Manager at MASA Architectural and Structural Design Lab until 2010, and subsequently completed the doctoral program in engineering at University of Tokyo Graduate School in 2012 as a research fellow for the Japan Society for the Promotion of Science. After a postdoctoral fellowship and Assistant Professor post at Tokyo University of Science, he became Associate Professor at the Graduate School of Kyushu University in 2016. He is currently Associate Guest Professor at Tokyo University of Science and Guest Research Fellow at the National Research Institute for Earth Science and Disaster Resilience.

Translation by Christopher Stephens

Interviewers: Masaaki Iwamoto, Akihiro Mizutani, Toshiaki Sato

Editors: Masaaki Iwamoto, Akihiro Mizutani

Illustrations courtesy of: Kyushu University / Shoei Yoh Archive, except where otherwise specified

Acknowledgment: The translation of this interview is supported by: JSPS KAKENHI Grant Number 21K14334

Interview in progress

Oguni Dome, exterior view (Photograph by Hajime Inoue)

Model of initial proposal for the Oguni Dome (barrel vault), exhibited at Forms in Wood (Tokyo, 1985)

Ingot Coffee Shop, exterior view

Music Atelier, interior view (Photograph by Yoh Design Office)

Oguni Dome, interior view (Photograph by Hajime Inoue)

Oguni Bus Terminal, interior view (Photograph by Yoh Design Office)

Oguni Dome, structural analysis diagram of roof. Blueprint by Taiyo Kogyo

Odawara Municipal Sports Complex Proposal, computer rendering

Galaxy Toyama Gymnasium, computer rendering (left) and photoelastic test analysis (right)

Oguni Dome under construction